Products with high availability and a range of mesh sizes from 5 µm to 125 mm

NEXOPART offers a wide range of test sieves, whether for manual sieving, conventional sieving, wet or dry sieving - you will find mesh sizes from 5 µm to 125 mm for analyzing your bulk material. Once you have found the right test sieve for you, you have nothing else to worry about. You do not have to wait long for your test sieve either. The components and materials for our test sieves are made in Germany, which means we can offer you high product availability and reasonably short delivery times. We also ensure short transportation routes and largely secure supply chains. At NEXOPART, you will always find the right standard-compliant test sieve for your sieving requirements - the test sieve that finds its way to you quickly.

Long service life and perfect performance for your test sieve.

To ensure the long service life of a test sieve, we at NEXOPART use high-quality frame materials and our team has developed an extremely stable sieve design. In particular, the smooth frame surface of the test sieve prevents cross-contamination so that the sieve mesh retains good tension even after intensive use. The meticulous workmanship of the NEXOPART test sieve assures you perfect performance. Rely on test sieves made in Germany. Rely on NEXOPART.

Test certificates and services for your test sieve.

On request, NEXOPART will provide you with extensive test certificates and services for sustainable and compliance-oriented quality assurance. Everything from recertification of the measuring equipment in our factory laboratory – tested in accordance with DIN EN 10204 with acceptance test certificate 3.1 – to accredited calibration of metal mesh test sieves in accordance with DIN EN ISO/IEC 17025. This ensures traceability to the national measurement standards.

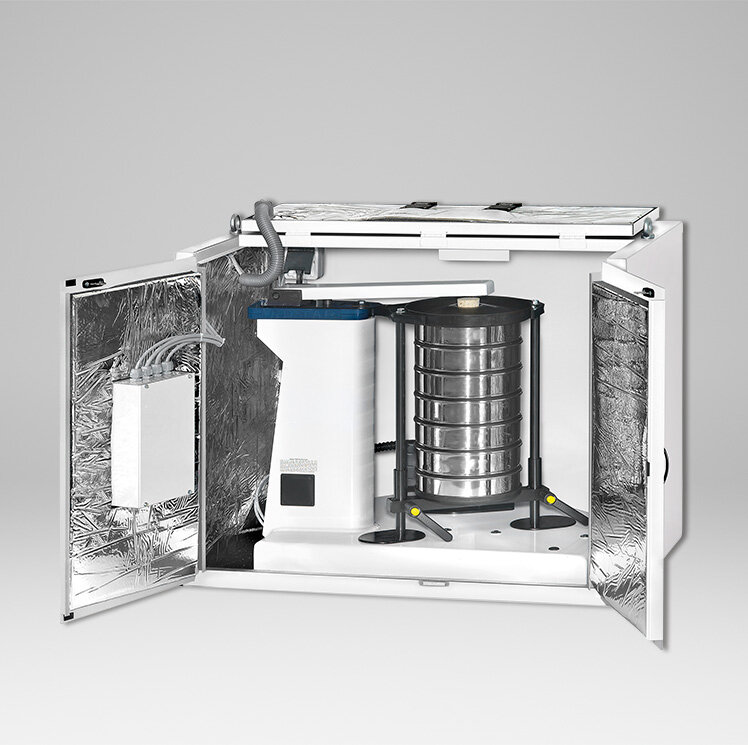

NEXOPART UFA. Ultrasonic frequency variation.

- step: Tighten the clamping ring around your NEXOPART test sieve.

- step: Mount the converter.

- step: connect generator and switch on.

Take a look at how the ultrasonic frequency variation simplifies your laboratory work

- minimized clogging tendency,

- destruction of agglomerates,

- higher sieving capacity and a shortened sieving time,

- low mechanical load on the sieve bottom + side effect cleaning of the sieve mesh,

- Parallel handling of several test sieves with only one generator (enables connection with two converters, twin operation)

Analog or digital ultrasonic frequency variation.

As a "plug-and-play" solution, you can attach the NEXOPART UFA in an analog or digital version conveniently, quickly and safely to all standard test sieves. The digital device allows you to excite several test sieves simultaneously with only one generator. With the help of the twin unit, it is even possible to connect two converters.

FAQ about a test sieve

What is a test sieve?

L

Why do you need a test sieve?

L

How expensive is a test sieve?

L

in our store.