Gentle, thorough, and energy efficient. NEXOPART USC.

Deposits and sticking particles decrease the permeability of the metal wire mesh sieve — and reduce the reproducibility and accuracy of your results. To thoroughly and gently remove the finest of particles from test sieves, NEXOPART offers the USC 200 S for test sieves with diameters up to 203 mm. You can use the NEXOPART USC 500 S for sieve diameters of up to 500 mm. And the best thing about it: These units clean more thoroughly than manual cleaning and save you time.

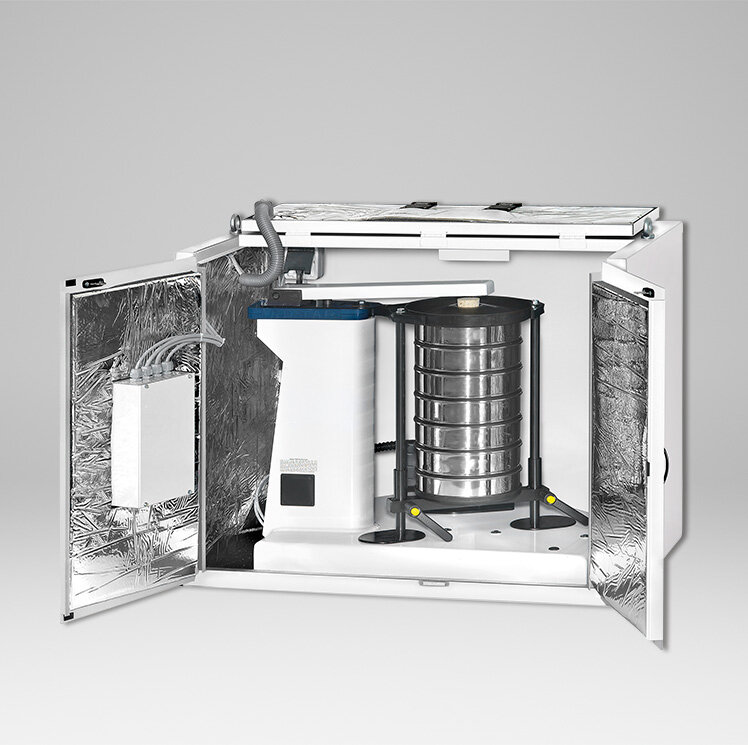

More needs more. USC 200 Multi.

Would you like to clean several sieves at the same time? No problem: With the NEXOPART USC 200 Multi you can clean a maximum of five test sieves with diameters up to 203 mm simultaneously. With NEXOPART, you don't have to forfeit easy handling and gentle cleaning of your measuring equipment.

Proper cleaning of the finest of mesh sizes – A practical tip for you:

Since they tend to tear easily, test sieves with fine mesh sizes of up to 500 µm must be cleaned in an ultrasonic bath. Do not use alkaline cleaning liquids, as they may damage the bonding. After the ultrasonic bath, rinse the test sieve with clear water and blow the sieve section out very carefully with compressed air to remove any streaks. Let the sieves drip dry for approx. 5 minutes and then dry in a lab oven for a maximum of 30 minutes at a temperature of 80°C - 100°C. You can remove any particles remaining in the sieve by gently tapping the sieve frame against a wooden block or a rubber pad. If at all possible, do not use a brush.