In the whitepaper you will find answers to the questions:

- What can a sieve analysis do - and what not?

- What are the reasons for a low sieve throughput?

- How do I obtain optimum sieving results?

- What do I have to consider in my sample preparation?

- How do I ensure that my test sieves function properly?

Tips and tricks - What is important?

Performing sieve analysis involves several complex steps that interlock seamlessly. Especially when sieving very fine material, even minor variations in the process parameters can lead to a reduction in sieving capacity and inaccurate results. Our white paper provides you with valuable information on what you should pay attention to when carrying out a precise, efficient and reproducible sieve analysis.

Outlook - What you can expect

Sieving method

Manual-, plan-, wet- or air jet sieving? The individual properties of your material determine which sieving method is most suitable.

Sieve parameters

Amplitude, interval, sieving time, sample weight - with the correct setting of the sieving parameters, you have an active influence on the quality and quantity of your measurement results.

Sieve support

Especially when separating very fine materials, the use of ultrasound significantly improves sieving performance and shortens sieving times.

Quick and easy to your free download

Fill out the form below and download the white paper.

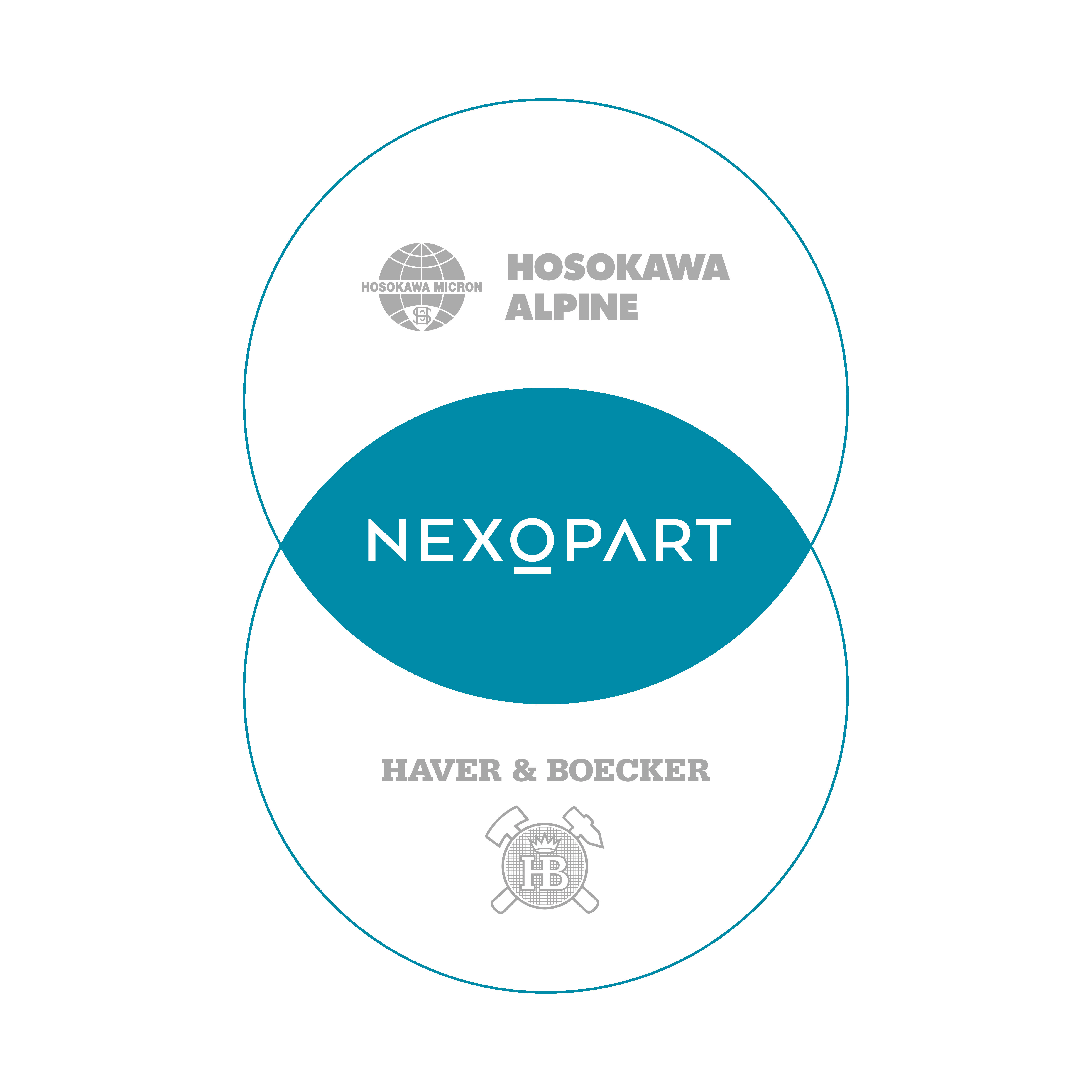

About NEXOPART

NEXOPART is a joint venture between Haver und Boecker oHG and Hosokawa Alpine AG. The foundation of NEXOPART is based on a hundred-year partnership between the two parent companies and, as a specialized premium supplier, offers all products and measuring equipment in the field of particle analysis for laboratory work under one roof.

NEXOPART provides you with all components for standard-compliant sieve analysis from a single source - from test sieves and test sieve machines to complete sieve analysis systems. Our reliable particle measurement technology has proven itself with hundreds of materials in various industries. You can use our measuring equipment for the finest powders in the pharmaceutical and chemical industries through to the quality control of coarse bulk materials such as coal, stones and soils.